Why Aspen Flexible Pack

Professional Flexible Packing

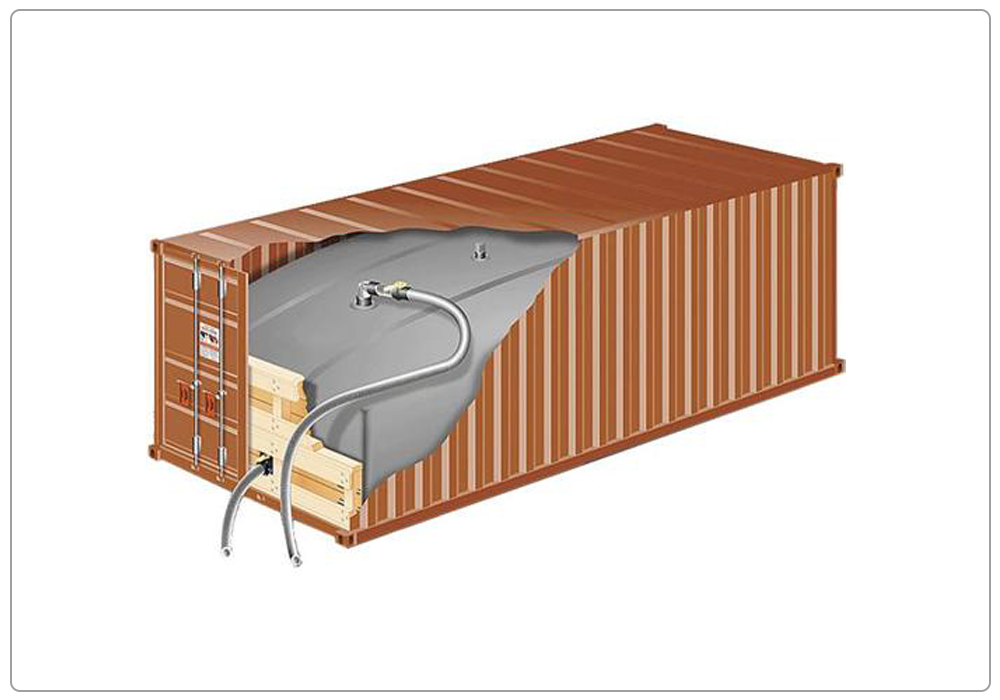

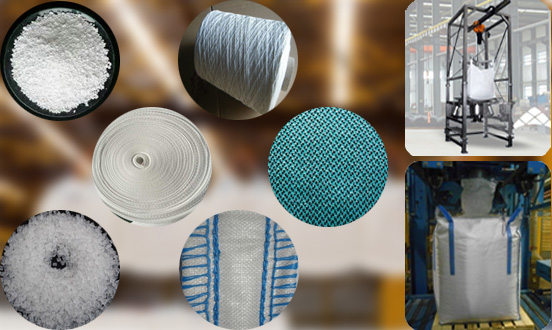

Aspen Group's professional technical team who have more than 10 years experience,basing on safety and cost-saving,provides customer the best specialies products. Aspen Group use the branded virgin plastic material PP/PE with stable formula strictly observe ISO 9001 and ROHS standard, widely applied in all kinds of package in Food, Vegetable, Chemical, Sand, Cement, Fertilizer, Rice, Flour, Sugar and other raw material. Aspen group grated the material with UV protection, inflaming retarding. Meanwhile,Aspen Group use the most advantage equipments and standard production process to guarantee the uniform quality and meet the GMP standard. Aspen Group's flexible packing products includes all kinds of dry bulk bags, sea bulk container liner,liquid flexitank bags. Each steps of producing process are finished by ourselves.

Thread Drawing

Thread-Drawing process is the first step to produce PP woven bags/ FIBC/Jumbo Bags/Super sacks,Digital Control automatic drawing machine served for Aspen Group, can stably draw out the qualified threads. It is very important for next step's fabrics weaving. Meanwhile,Aspen Group consist in testing thread's physical property in each batch to guarantee the finish products' quality. The physical property testing contents includes: Anti-UV, Breaking Strength, Tensile strength,Elongation at break and anti-static electricity (option).

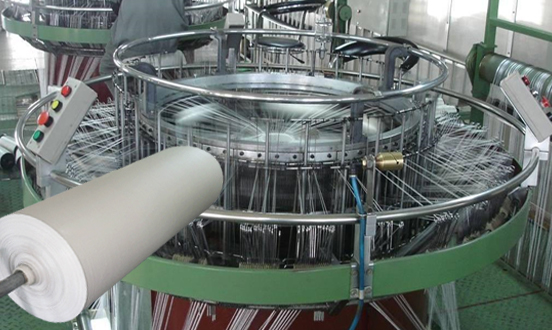

Fabric Loom

Max 4 meterts double-folder width 50g/m2 - 300g/m2 fabrics thickness (not including the coating) Max 3 layers composite (2 layers pp woven fabrics and middle 1 layer PE coating) Rib reinforcement design according to the payload demands Max warp and weft density 56 threads/10cm High performance UV 2%-5% high performance UV additive Anti-static Formula avoid poweder remain and stive exploding(Option) Ventilatable Mesh fabrics for fresh packaging according to customers demand

Other Accessories

Other Accessories includes:lift Loops, Film Coating, Inner Bags, Thermal Bonding Bags and other spare parts. Lift Loops: Full loops, Sleeve Lift,Cross-corner loops,Side-seam Loops, Ancillary loops, Single/Double stevedore straps and Hood lifts etc. Film Coating: Outside film Coating, Middle film Coating and Inside film Coating Inner Bags: Most of Inner Bags by film thermal bonded Thermal Bonding Bags: Liquid bags, high strength composite material Other Spare Parts: Steel Carabiner, Plastic rope and Steel Bars etc.

Sewing Team

Aspen Group's sewing workshop set up in strict accordance with ISO9001,ISO13485,FDA and GMP, more than 4 dust-free and non-toxic workshops. All sewing workers must wear anti-infection caps and clothing. All equipments must follow food grade standard.

How Quality Control

Aspen Group strict quality control on each steps: Step-1: Plastic, additive and other formula element specifications testing Step-2: Fabric physical property testing including strength, expanding… Step-3: Other accessories specifications quality control: loop thread etc Step-4: Sewing process control a single needle or a piece of thread Step-5: Finish products test including volume ratio, payload and drop test